Welcome to the official website of Guangdong SCREWE mechanical equipment Co., Ltd

+86 0760-23639163

- 商品詳情

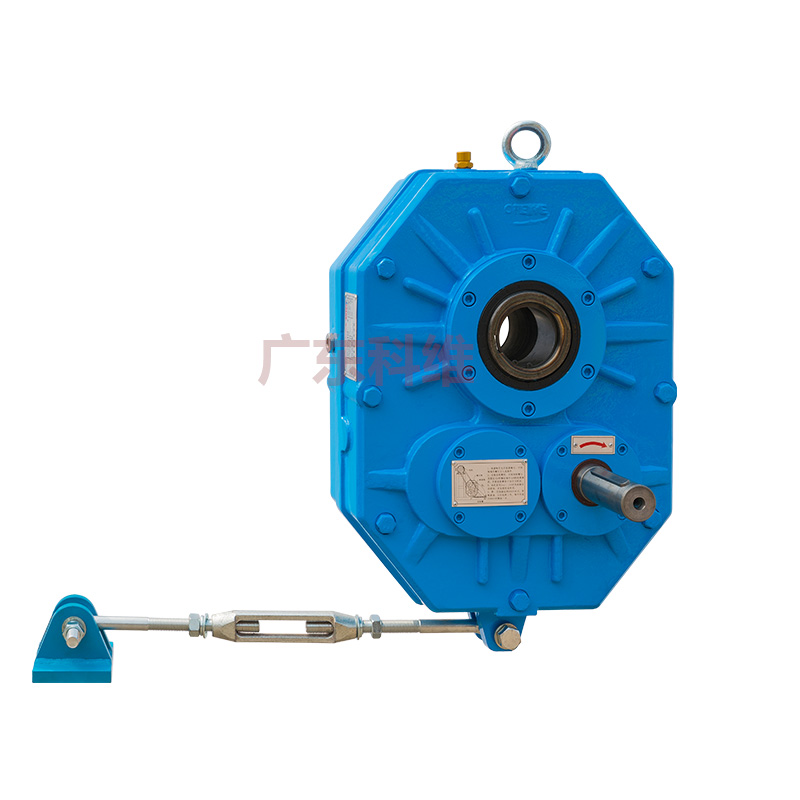

WG suspension reducer

Product features

● Vertical reducer, ductile iron box, square corner design, reasonable structure and beautiful appearance.

● Involute hard tooth surface grinding gear, two- -level deceleration, smooth operation, and low noise.

● Reverse stop device installed to prevent reverse rotation during sudden power interruption, and easy to adjust the rotation in clockwise and counterclockwise.

● Adjustable tension rod.

Product Applications

This type of machine is mainly used in mining, metallurgy,building materials, chemical, light industry and other public mechanical equipment deceleration drive and suitable for the use of horizontal installation.

Specification parameters

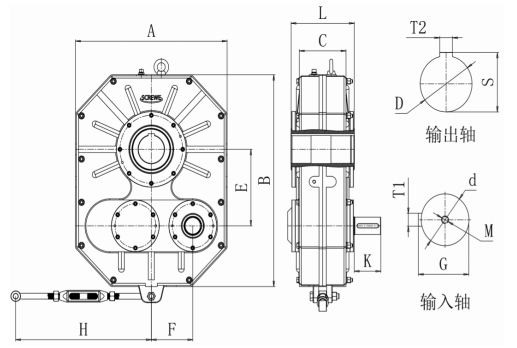

| Basic dimensions | |||||||||||||||||

| Model | 減速比 i= | Overall dimension | Input shaft(mm) | Output shaft(mm) | Weight(kg) | ||||||||||||

| A | B | C | E | F | H | d | G | K | M | T1 | D | S | L | T2 | |||

| WG-50 | 16 | 342 | 450 | 120 | 145 | 65 | 580-710 | ∮38 | 41 | 80 | M12x30 | 10 | ∮60 | 64.4 | 170 | 18 | 68 |

| WG-100 | 17.4 | 384 | 520 | 136 | 174.5 | 80 | 580-710 | ∮42 | 45 | 110 | M12x30 | 12 | ∮70 | 74.9 | 202 | 20 | 110 |

| WG-200 | 16.9 | 490 | 630 | 166 | 202.7 | 95 | 580-710 | ∮48 | 52 | 110 | M12x30 | 14 | ∮85 | 90.4 | 240 | 22 | 218 |

| WG-200A | 16.9 | 490 | 630 | 166 | 202.7 | 95 | 580-710 | ∮48 | 52 | 110 | M12x30 | 14 | ∮90 | 95.4 | 240 | 25 | 218 |

| WG-300 | 15.4 | 570 | 720 | 204 | 241 | 113.5 | 580-710 | ∮55 | 59 | 110 | M12x30 | 16 | ∮100 | 106.4 | 276 | 28 | 320 |

| WG-350 | 15.4 | 570 | 720 | 212 | 241 | 113.5 | 580-710 | ∮65 | 69 | 140 | M12x30 | 18 | ∮120 | 127.4 | 330 | 32 | 390 |

| WG-400 | 18.6 | 760 | 980 | 234 | 354 | 208 | 650-800 | ∮80 | 84.5 | 163 | M12x30 | 20 | ∮130 | 137.4 | 317 | 32 | 660 |

| WG-50(500) | WG-100(500) | WG-200/WG-200A(500) | WG-300(630) | WG-350(630) | WG-400(1000) | ||||||||||||

| P2 | n2 | M2 | P2 | n2 | M2 | P2 | n2 | M2 | P2 | n2 | M2 | P2 | n2 | M2 | P2 | n2 | M2 |

| Kw | rpm | Nm | Kw | rpm | Nm | Kw | rpm | Nm | Kw | rpm | Nm | Kw | rpm | Nm | Kw | rpm | Nm |

| 7.5 | 96 | 720 | 11 | 96 | 1060 | 15 | 96 | 1460 | 30 | 76 | 3700 | 30 | 76 | 3700 | 55 | 48 | 10700 |

| 11 | 96 | 1060 | 15 | 96 | 1460 | 18.5 | 96 | 1800 | 37 | 76 | 4580 | 37 | 76 | 4580 | 75 | 48 | 14700 |

| 15 | 96 | 1460 | 18.5 | 96 | 1800 | 22 | 96 | 2140 | 45 | 76 | 5580 | 45 | 76 | 5580 | 90 | 48 | 17600 |

| 18.5 | 96 | 1800 | 22 | 96 | 2140 | 30 | 96 | 2920 | 55 | 76 | 6780 | 55 | 76 | 6780 | 110 | 48 | 21500 |

| 37 | 96 | 3620 | 75 | 76 | 9000 | ||||||||||||

| Note: P2 is the motor power, N2 is the output speed of the reducer (corresponding to the linear speed of the conveyor belt of 2.5 m / s), and M2 is the output torque of the reducer. | |||||||||||||||||